CNC

Fiber Laser

Increase your productivity

with the highest precision possible.

Structure

4 mm (0.157″) welded steel

Motor

Yaskawa servomotor

Download the data sheet

For all of your

power needs.

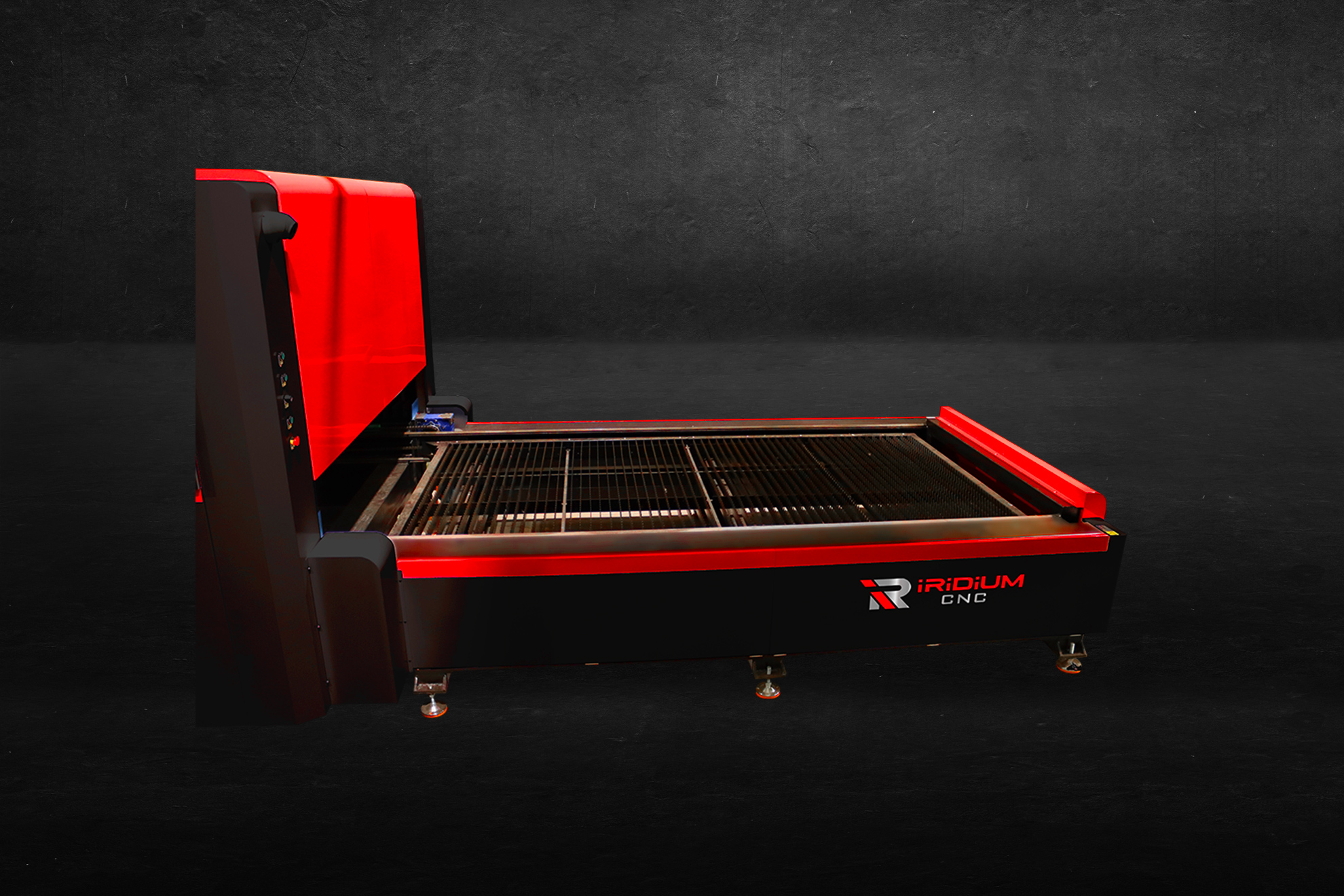

– Several sizes available: 4×4, 4×8, 5×10, 5×12

– Possibilities:

- With or without a protective cage

- With or without an exchange table

When you buy

(starting at)

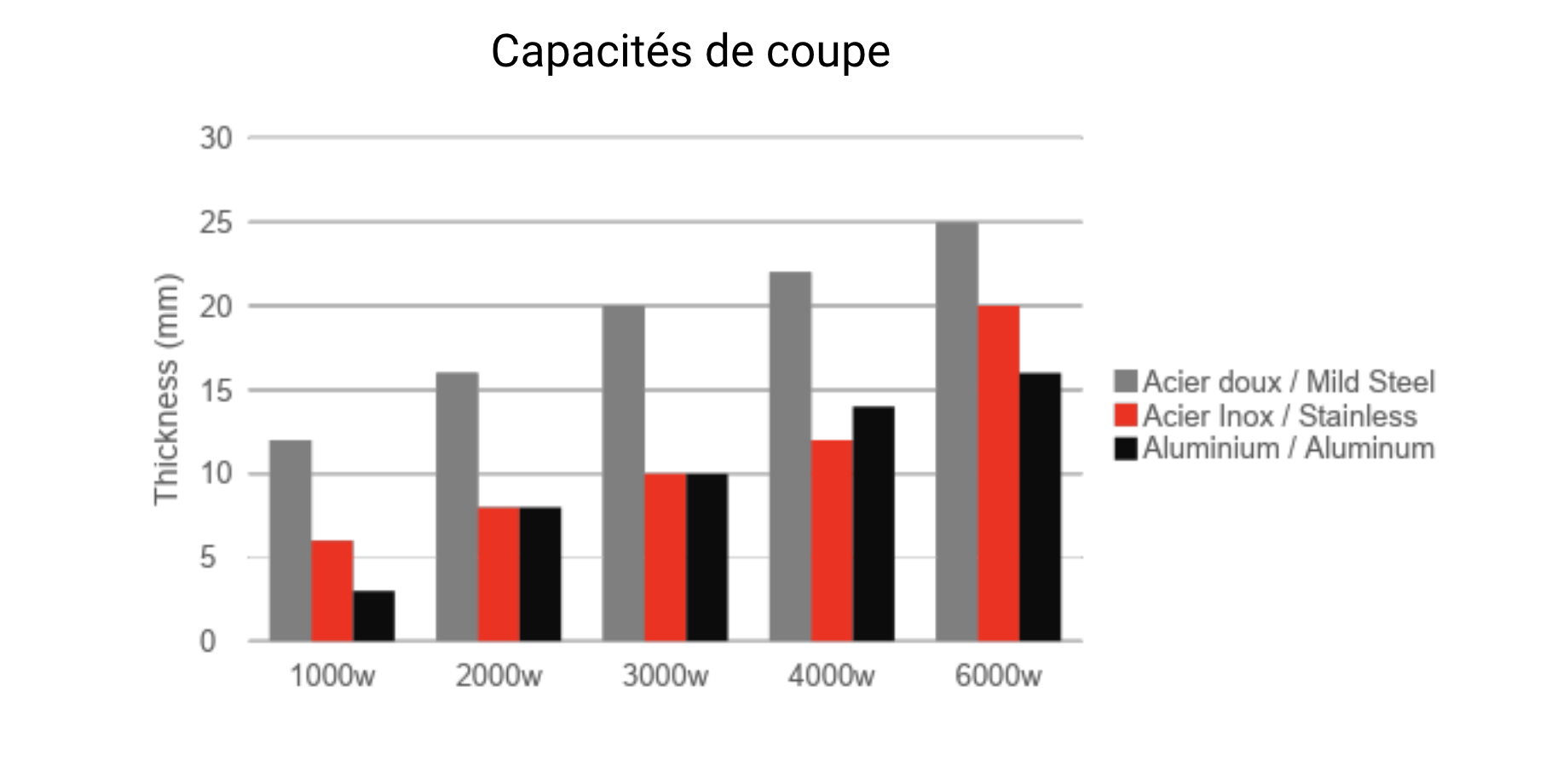

1000 w

2000 w

3000 w

4000 w

1000 w 120 000 $

2000 w 140 000 $

3000 w 170 000 $

4000 w 190 000 $

Price

to sell

120 000 $

140 000 $

170 000 $

190 000 $

– Monthly rental available.

Contact us.

Technical Data

Size

Possibilities

Open table, safety enclosure, exchange table

Structure

Cutting head

Motor

Displacement

Z-axis

Anti-collision system

Focus type

Travel speed 1,200 in/min.

Z ball screws

Contactless automated cutting height

Automatic

SIPG Source

Laser source guaranteed for 3 years

IPG energy efficiency: 30% (in contrast to competitive fiber discs) 20%.

Electrical input

Laser source

Depends on the laser power.

Platforme

Remote support

Windows

TeamViewer

Options

Safety enclosure

Exchange table

Included

5-year* warranty

English & French

technical support

After-sale service

Training*

Best warranty

in the industry

610 mm (24″),

screen, keyboard and mouse

Ultra fast Ethernet

communication

Programming software license

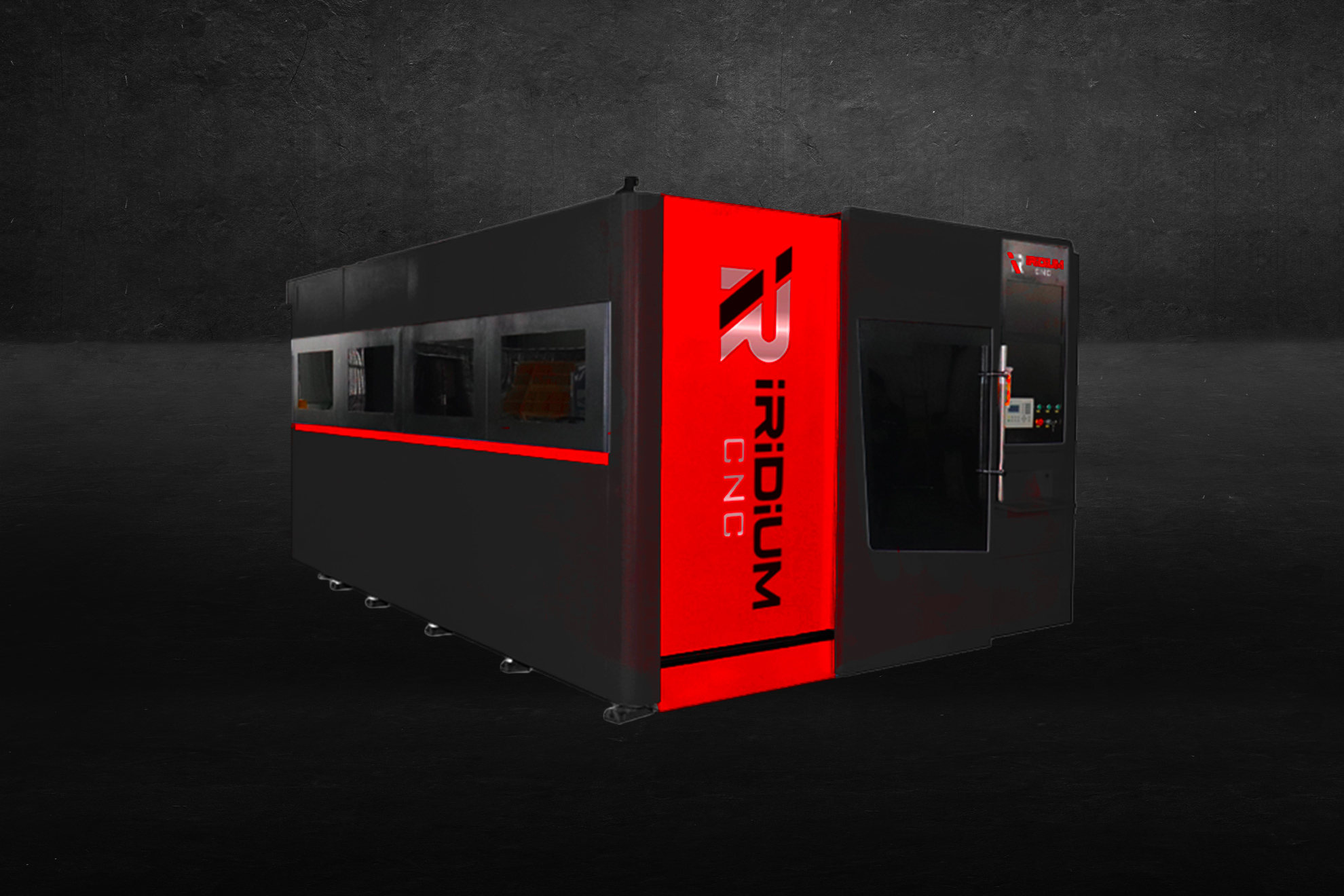

Our fiber laser tables are the solution to give you the flexibility your business needs. Thanks to their patented optical technology, they enable precise cutting of a wide range of materials, from steel to aluminum, including non-metallic materials. Designed to produce parts of the highest quality at unrivalled speed.

They can be customized to suit your needs, your type of production or your budget.

Our laser tables are powered by IPG laser sources, reliable, high-performance and renowned for their power and quality. They are the world leader in high-power fiber-optic lasers and amplifiers.

Frequently Asked Question

What is a Fiber Laser machine?

A fiber laser machine is an innovative tool engineered to deliver unmatched precision in cutting, engraving, and marking. By utilizing fiber optics doped with ytterbium, these machines generate an exceptionally focused laser beam, ideal for working with a wide range of materials including metals, ceramics, and plastics. The combination of a fiber laser head with a stepper motor control system allows for rapid operation and remarkable stability over time. This makes fiber laser machines not only versatile but also highly reliable for industries that demand accuracy and efficiency. The advanced technology ensures smooth workflows, consistent outputs, and minimal errors, making them an indispensable asset for modern manufacturing and design.

- Precise and Versatile: Fiber lasers create extremely accurate laser paths for intricate patterns or industrial-grade cuts.

- High-Speed Scanning: Achieve faster production cycles without compromising precision.

- Stable Over Time: Robust designs ensure long-term, consistent performance in demanding environments.

- Works on Multiple Materials: Suitable for stainless steel, titanium, aluminum, and certain plastics.

What are the advantages and uses of Fiber Laser machines?

Fiber laser machines stand out due to their high power density, operational efficiency, and precision, making them an industry favorite for various applications. These machines utilize cutting-edge laser technology to penetrate deeply into tough materials while maintaining accuracy. The lasers are highly focused, creating consistent, flawless results across every project. Additionally, their ability to convert electrical energy into laser energy with minimal waste ensures cost efficiency over time. They are widely used in industries requiring high-volume production and intricate detailing, offering solutions that meet diverse business needs.

- Power and Depth: Fiber lasers penetrate materials like stainless steel and titanium to create deep, clean cuts.

- Precision and Consistency: Produces consistent engravings and markings even on complex surfaces.

- Energy Efficient: Minimizes energy wastage while offering long-lasting performance.

- Ideal for High-Volume Work: Fast operation speeds allow bulk production without compromising quality.

What are the key features to look for in a Fiber Laser machine?

The design and technology of a fiber laser machine greatly impact its performance, durability, and ease of use. Ensuring the right features can significantly enhance your production output while reducing costs. High-quality machines include advanced industrial controllers, precision-engineered frames, and state-of-the-art laser systems. Features such as real-time visualization, compatibility with CAD software, and optimized toolpath technologies are standard in most models. These attributes not only increase accuracy but also allow faster production cycles and reduced waste.

- Precision Engineering: Heavy-duty frames ensure vibration-free operation for better accuracy.

- Advanced Controllers: Intuitive PC-based controls for seamless user experiences and better optimization.

- Compatibility: Works with popular CAD and CAM software for flexible design capabilities.

- Real-Time Monitoring: OpenGL graphics offer live feedback for better process control.

How to operate a Fiber Laser machine safely and efficiently?

Safety is a top priority when working with high-powered laser machines. Fiber lasers operate at extremely high intensities, which can pose risks to both operators and the surrounding environment if proper protocols are not followed. Ensuring safe practices not only protects users but also prolongs the life of the equipment. This includes wearing protective eyewear, maintaining a clean workspace, and adhering to manufacturer-recommended guidelines. Proper ventilation and the use of non-flammable materials further minimize hazards, while routine inspections help identify any potential issues before they escalate.

- Eye and Skin Safety: Always wear certified laser safety glasses.

- Workspace Preparedness: Keep flammable materials away and ensure proper ventilation.

- Routine Maintenance: Regularly clean and inspect the machine to maintain peak performance.

- Follow Guidelines: Rely on the user manual and safety training to handle equipment properly.

What are the tips for optimizing Fiber Laser engraving and cutting?

Achieving the best results with a fiber laser machine requires attention to detail and a willingness to experiment with settings. Every material has unique properties that demand adjustments in laser power, speed, and focus. Aligning and securing materials properly ensures precise cuts, while nesting techniques can reduce material waste. Operators are encouraged to experiment with machine parameters to discover optimal configurations for their specific applications. Additionally, keeping the workspace clean and debris-free prevents interruptions, ensuring uninterrupted workflows.

- Material-Specific Settings: Fine-tune speed and power based on the material in use.

- Precise Alignment: Properly align and secure materials for optimal accuracy.

- Explore Techniques: Use nesting and layering for cost-effective production.

- Regular Upgrades: Consider software updates to improve machine functionality.

How to maintain and upkeep Fiber Laser machines?

Fiber laser machines require regular maintenance to function efficiently and avoid costly downtime. A well-maintained machine will deliver consistent results, reduce wear and tear, and extend its lifespan. Cleaning the laser head, lenses, and filters ensures a clear, focused beam, while checking for worn-out parts prevents unexpected failures. Adhering to the manufacturer’s recommended schedule for servicing and replacements will also help keep your machine operating at peak capacity. Proper environmental conditions, such as dust-free surroundings and controlled humidity, further enhance performance and reliability.

- Clean Components: Regularly clean lenses, mirrors, and filters to ensure precision.

- Inspect Regularly: Identify and replace worn parts before they cause damage.

- Adhere to Schedules: Follow recommended maintenance timelines for optimum results.

- Environmental Care: Store machines in clean, dry environments to prevent degradation.

Transform Your Production Process with Iridium CNC Fiber Laser and Fiber Laser Marking Machines!

Contact us today for precision-engineered solutions, cutting-edge technology, and unparalleled support tailored to your business needs. Our team is here to help you achieve efficiency, quality, and success in every project!

We can advise you

and answer all of your questions.

Contact us

*Certain conditions apply.